2. Please use the equipment in a room of temperature between 20 ~

25 ℃, and its fluctuation range control at ±1℃.

3. Please control the temperature of the cutting water at 22 ~ 27

℃(variation ranges in ±1℃ ), the cooling water at 20 ~ 25 DEG C

(variation ranges within plus or ±1℃).

4. Please avoid the equipment to be impacted and any vibration of

the outside world. In addition, please do not install the equipment

near the device like blower and vent that produces a high

temperature and a device that generates oil mist.

5. Please avoid the equipment to be impacted and any vibration of

the outside world. In addition, please do not install the equipment

near the device like blower and vent that produces a high

temperature and a device that generates oil mist.

6. Please follow the product manual we provided for operation

strictly.

Full Auto Dicing System YSL-2000AD Features of products

1.Using touching LCD to operate. The interface design is simple and

easy. Provide a variety of languages such as Chinese, English,

Korean, etc.

2. Feeding, position align, cutting, cleaning / drying and

unloading all automatically completed.

3. Can meet the high precision cutting maximum diameter of 300 mm

materials.

4.Double spindle cutting simultaneously, more than 85% higher than

that of single spindle cutting capacity.

5.CCD automatic align.6.Real-time monitoring system of the pressure, water pressure,

current, etc., to avoid damage to the air spindle.

7.Dicing spindle: 2.4 kw × 2set (Max: 60,000 rpm)

8.Repeat positioning accuracy : 0.001mm

9.Cutting speed: 0.05 ~ 400 mm/sec

10.Each magazine can be stored 20 ~ 30 layers of frame.

11.Standard collocation of using blade size: 2 Inch(Max:3 Inch)

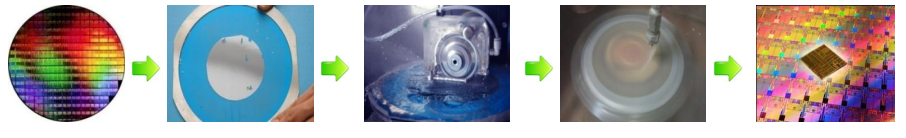

Processdescription

1.Mechanism remove it from magazine, and send it to the temporary

table.

2.Unloading robot will move the dicing material tochunk.fordicing

process.

3.Feeding robot move the dicing material to the cleaning platform

for cleaning and drying process.

4.Unloading robot send material having been cleaned and dried to

the temporarytable.

5.Robot send the dicing material to the magazine .

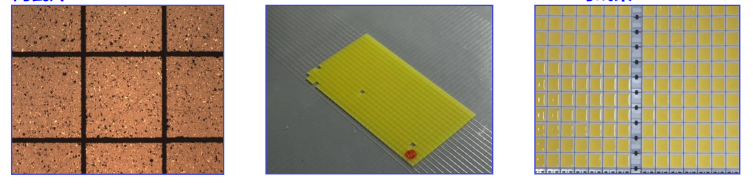

Case Sharing