Features

1. It can be connected to the assembly line, and the automatic

cutting of the board can be realized without manual labor, and the

split PCB flows out through the assembly line;

2. It is quick and time-saving to change products,just change the

program;

3. Multiple safety control modes: structure foolproof, light

curtain control, software control;

4. Microcomputer control, man-machine exchange interface. easy to

understand;

5. Data monitoring system: boot time monitoring, capacity

monitoring, fault monitoring, etc.

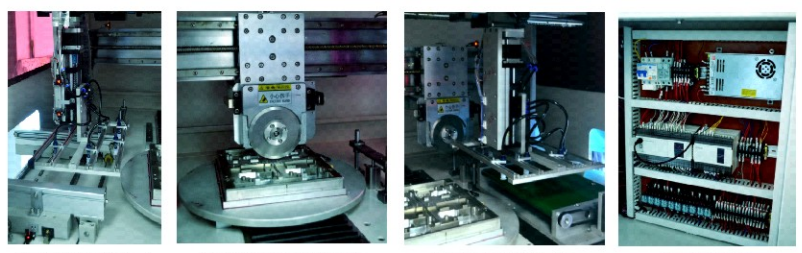

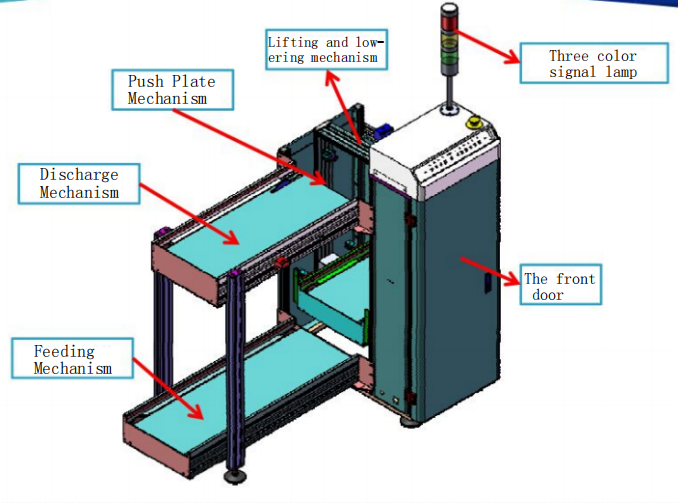

Universal plate 360 degree Universal plate International standard

taking device divider console collection device and electrical control system

waste collection system

Features of machine

1. High degree of automation: on-line, automatic feeding, automatic

cutting, automatic feeding, automatic plate edge loss, static

positioning discharge, belt discharge optional.

2. Wide application range: V groove XY both sides to slitting,

suitable for slitting aluminum substrate, copper substrate, FR4 and

other plates.

3. Special cutter mechanism, effectively reduce cutting stress.

4. It can store 50 groups of programs, and the fixture can do fast

positioning and quick production change.

5. The whole machine adopts Mitsubishi PLC+ Wilenton touch screen

control, the operation interface is simple.

6. Independent research and development, strong scalability.

7. Famous brands are selected for the parts, and special treatment

is made with the round cutter. Less wearing parts.

8. Built-in vacuum cleaner, small footprint.

9. Equipped with ion air gun to effectively remove cutting static

electricity.

| Machine specifications |

| Item | Technical parameters |

| Equipment brand | YUSH |

| Device name | Online V slot double-sided PCB depaneling machine |

| Device model | YSV-8A |

| Operating Voltage | AC220V 50/60HZ |

| Power | 1800W |

| Operating system | Touch screen |

| Interface | PLC Human-machine exchange interface |

| Board area | 300*350MM Accept customization |

| Board thickness | 0.5~3.5MM |

| Exterior | Baking paint white |

| Working pressure | 0.4-0.7MP |

| Board material | Fiberboard.aluminum substrate, copper board, cardboard, ETC. |

| Feeding mode | Online transport guide |

| Receiving mode | Belt transmission |

| Moving speed | 1000MM/S Adjustable |

| Transfer speed | 500MM/S Adjustable |

| Safety devices | Safety electric eye device and structure foolproof |

| Machine weight | 600KG |

| Physical dimension | 1300*1450*1650MM |

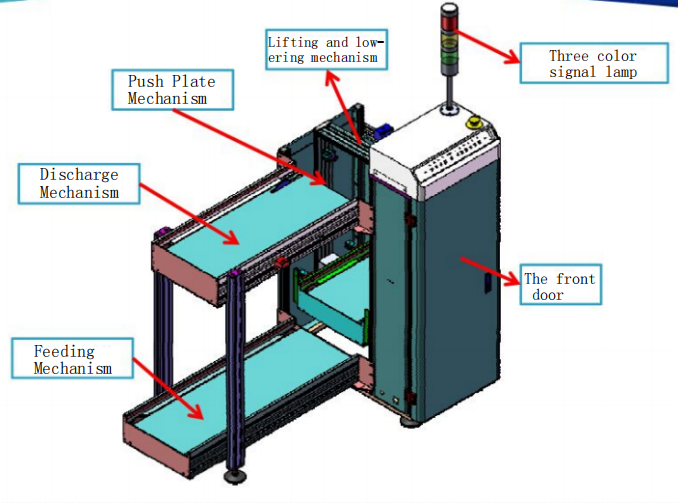

Description of machine function parameters

1. This device is suitable for PCB board division work after

plug-in.

2. With automatic feeding/automatic cutting/automatic receiving

plate and other functions, the machine is simple and fast.

3. The setting of various parameters fully ensures the continuity

of feeding board and sub-board.

4. The main transmission parts adopt Zhongyan precision stepper

motor (Mitsubishi servo motor) and SMC pneumatic components, with

high repeat positioning accuracy.

5. The whole machine adopts Mitsubishi PLC+ Velen touch screen

control, the operation interface is simple and convenient

6. Working voltage of the equipment: 220 V 50HZ

7. Efficiency: 15s/pcs (150*150mm eight cuts for reference)

8. The working area is protected by safety grating

Automatic Loader Machine

Connect the feeding module of Automatic Loader Machine and

Automatic Depaneling Machine

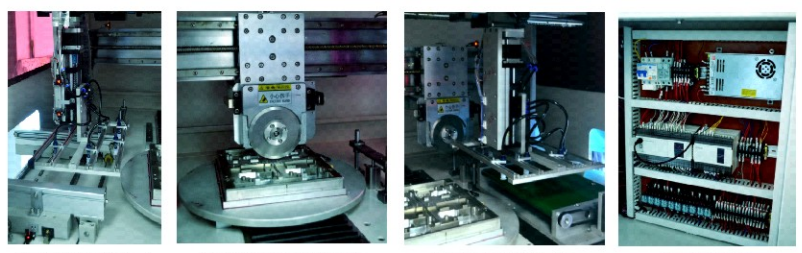

Machine split-board action description

1. One machine is equipped with a cutter cutter die module. The PCB

board is sent to the predetermined track through the loading

mechanism; The manipulator moves over and uses the vacuum nozzle to

place the PCB board on the cutter die of the slitter machine.

2. PCB board is placed after the lower tool die module; Move to the

slitter position, the round knife on the machine translation

slitter PCB board, after the translation slitter position, the

lower cutter die module is moved to the slitter position; Until the

transverse plate is finished, the rotary cylinder automatically

rotates 90 degrees to cut the vertical plate.

3. After the machine finishes cutting PCB board, the cutter die

tool group exits; Take the plate manipulator to move over and cut

it

The PCB board and the board waste edge are sucked up at the same

time, moved to the waste frame to drop the waste, and then moved to

the collection

The product is arranged on the plate plate and sent away by the

transport line.

4. There is an industrial vacuum cleaner under the cutting die of

the machine to absorb PCB dust. Work in this cycle.

Note: The cut pieces of small PCB board can be automatically placed

in the material box (material) according to customer's requirements

Tray, or placed directly on the assembly line) to be carried away

by the assembly line.

Brief description of machine

1. Automatic on-line V-slot splitter can further improve the

quality of splitter; V slot X and Y can be automatically slitted,

and the slitting of aluminum substrate (300-1500MM), copper

substrate, FR4 and fiberglass board is clean and burr free.

2. The splitter can be connected to the assembly line to realize

automatic splitter. No manual plate; The cut plate is carried away

by the assembly line, which greatly saves manpower and completely

realizes the operation of unmanned sub-board.

3. When changing products, the tool die part and the suction cup

part can be exchanged directly, without manual adjustment, which

greatly saves time.