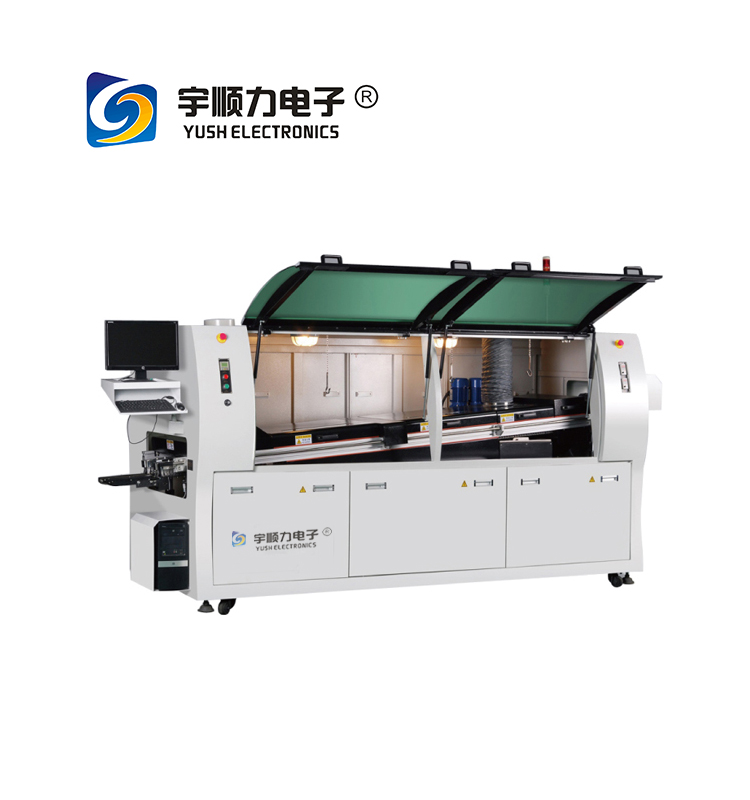

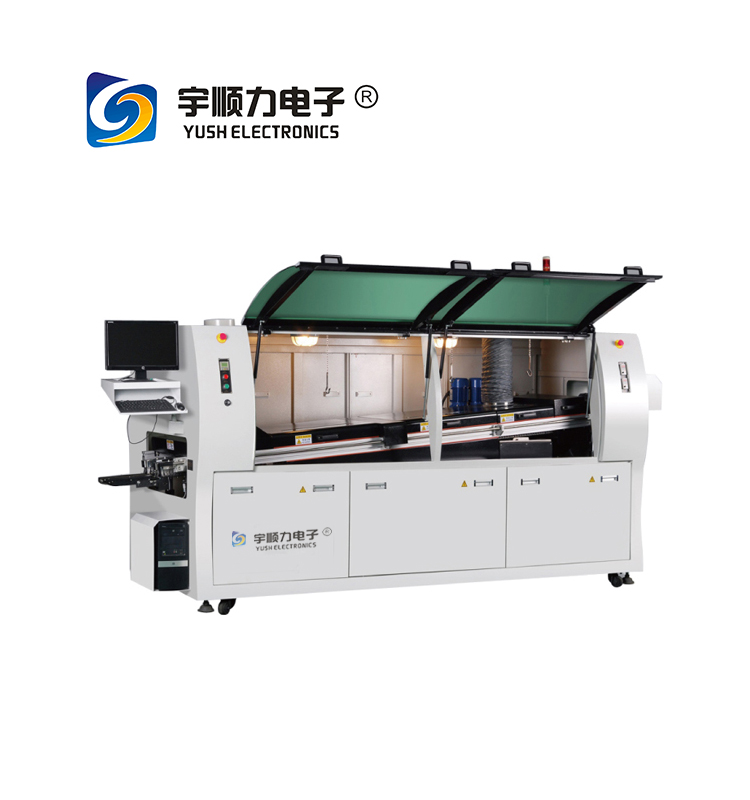

Practical Lead-free wave soldering machine for making LED light

Specifications

| Model No. | Yush N350 |

| Number of pre-heaters | 3 |

| Pre-heater passage | 1600mm |

| Body size | 3300(L)*1400(W)*1560(H) |

| Outside dimension | 4100(L)*1400(W)*1560(H) |

| Weight | 1100KG |

| Total/steady consumption | 24KW/6-8KW |

| Air supply | 0.5MPa |

| Preheating style | Hot air |

| Preheater consumption | 220V 8KW |

| Control method | PC +PLC |

| Range of temp. set-point | Room temperature---300ºC |

| Preheating time | About 10-15mins for setting 150ºC |

| Solder application | Lead-free |

| Solder pot capacity | 320KG |

| Solder pot temperature | 300ºC |

| Solder pot consumption | 380V 12KW |

| Solder temp. control method | PID&SSR |

| Wave motor consumption | 1KW 220V |

| Solder melting | About 120mins for setting 250ºC |

| PCB width | 50-350mm |

| Conveyor speed | 300-2000mm/min |

| Conveyor direction | L→R (R→L optional) |

| Conveyor inclination | 4-7 º |

| Flux pressure/capacity | 3-5 bar/6.5L |

Product Description

1. Automatic conveying power system and auto synchronous board

feeding functions.

2.Tin stove peak uses frequency conversing speed adjustment which

can independently control the wave peak height.

3.Flux sprays system using scanning spray nozzle, Japanese nozzles

and rodless pneumatic cylinders and PLC control, accurate and

reliable.

4. PLC is used to control the machine, to ensure the reliability

and stability of the system.

5.With Remote Infrared Ceramic heating pipe preheating device, heat

radiation directly to the circuit board bottom, fast heating and

stimulate the full activity of flux.

6.Special alloy transportation chain claws, non-stick tin and

ensures the quality of welding PCB board.

7.Tin stove adopts imported high frequency conversion motor

independent control, stable performance.

8. Lead-free solder furnace with independent design, environment

protection and safety, easy to clean.

9. Preheating system uses three independent temperature control so

that ensure the excellent heat preservation, temperature

uniformity, temperature difference no more than ±2ºC.

10.Time can be controlled, we can preset switch functions, tin

stove can heat within 90 minutes.

11.Reasonable design and sensitive fault security alarm system

ensure the stable performance and operators’ safety.

Heating motor.

Patented titanium alloy chain claw, non-stick tin, never deformed,

long life, stable and reliable transport PCB. Equipped with a

cooling module (optional with a cooling fan), it is suitable for

lead-free multi-process requirements.

The whole titanium tin furnace has a function of automatic entry

and exit of the tin furnace, and the double wave peak passes

through the frequency converter to independently control the double

peak height.

1, our service tenet: fast, thoughtful and thorough

2, service goals: service quality to win the user satisfaction

3. the service efficiency: the warranty period or the warranty as

equipment failure, the supplier in the receipt of the notification,

the maintenance personnel in one hour to respone.

4, service principle: product wave soldering machine warranty

period of 12 months, in the guarantee period the supplier will free

maintenance and replacement of quality caused by the damaged wave

soldering machine parts.

Packaging